This lab was prepared by Dr. S. Li for students taking CIVI 484 Hydraulic Engineering in Fall, 2009 at Concordia University.

This experiment is about energy head losses in pipe flow. Energy head losses always occur in pipe flow due to skin friction on the pipe wall. Additional energy head losses occur due to disturbances to pipe flow streamlines triggered by valves and such pipe fittings as bends, sudden expansions and contractions.

Energy Equation Between cross section 1 at upstream and cross section 2 at downstream along a pipe (the figure below), we may write the energy equation

where P is pressure, λ is the specific weight of water, z is elevation, V is flow velocity, g is the gravitational acceleration, and hL is the energy head loss that has occurred between the two cross sections. The subscripts 1 and 2 refer to cross section 1 and cross section 2, respectively.

Energy Loss in a Straight Pipe

Consider pipe flow through a straight section of a pipe free from fittings. The energy loss caused by skin friction on the pipe wall can be expressed as

where f is the Darcy friction factor, L is the length over which the loss has occurred, and D is the diameter of the pipe. The Darcy friction factor can be determined experimentally. However, in most cases, it is directly obtained from the Moody diagram. The Moody diagram shows two limiting cases: f for laminar flow,f for turbulent flow. Under these conditions, f can be derived theoretically or determined using an empirical correlation.

Energy Loss in Fittings

In addition to the energy loss caused by skin friction, energy losses result from pipe fittings. This is because the pipe fittings disturb flow velocity streamlines. We relate the additional energy loss due to a pipe fitting, hloss, to the local velocity head, through a loss coefficient, K

From measurements of the additional energy loss and the flow velocity, we can determine the coefficient.

Procedure

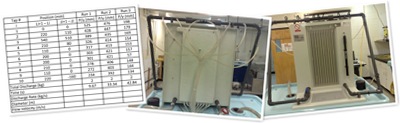

Students use a closed pipe flow system called Flow Bench F1-21, manufactured by Armfield Engineering Education. The main components of the system are:

• a pump • closed pipe sections

• a steelyard

• a manometer board connected to ten pressure taps

• a valve for flow rate control

• pressure taps at ten locations along the pipe

• a hand pump

(1) Place the bench on a level platform.

(2) Check the gate valves to ensure the inlet and outlet valves of the pump are open.

(3) Start the pump.

(4) Set the flow rate by adjusting the valve for flow rate control.

(5) Record the values for the pressure head at ten locations along the pipe flow. These

values are indicated on the manometer board. Use the hand pump for

pressurization of manometers.

(6) Record the total discharge by weight over the period of each experiment run.

(7) Record the run time of the experiment.

(8) Record the diameter of the pipe sections along the path of the flow.

Calculations

(1) From standard textbooks or hydraulic field manuals, find the roughness height of the pipe material ε . Determine the relative roughness, ε / D, where D is the diameter of a pipe section.

(2) Find the friction factor f in equation (2).

(3) Find coefficient CHW in the Hazen-Williams equation. The equation is of the form

where Rh is the hydraulic radius, and S is the slope.

Raw data and diagrams:

You can download the raw data in Excel format here.

Results

TBD after the lab has been submitted. Meanwhile, here are some more photos of Group 1 in action.

what is the application of this in engineering???

ReplyDeleteHi eDY,

DeleteOne application would be to determine how much power a pump would need in order to overcome the energy losses due to friction while providing a specified flow rate.

All the best!

Hello! I've been reading your blog for some time now and finally got the bravery to go ahead and give you a shout out from Lubbock Texas! Just wanted to mention keep up the good work!

ReplyDeleteLook at my homepage Bad Diets